Cabinet feature

Safety Design

The main electrical room adopts an independent isolation chamber design and is equipped with safety interlock equipment. ES and electrical room box doors are interlock controlled,

high-sensitivity water immersion alarm, explosion-proof protection design, main circuit temperature and humidity monitoring, outer shell grounding continuity performance DC30A.

Low Carbon Sustainability

Taiwan's largest copper busbar manufacturer, employing flat twisting to replace multi-segment connections, saving energy consumption with quality control from the start.

Modularization

Assembly error rate reduced to the lowest, maximizing productivity.

User-Friendly

Design allows quick removal and insertion of repair units, saving maintenance time and labor costs.

Green Manufacturing

Pin assembly without welding, reducing pollution caused by welding, and lowering the cost of replacing units,

no need to reprocess the outer shell.

Space Saving

The cabinet's exterior is designed to be compact and solid, saving space for substations.

Technical Specifications

| Item | Specified Specifications | Unit | Set Parameters | |||||

| 1 | Panel Dimensions (W×D×H) | mm | 800(1000)×1910×2530 ※Special specifications are welcome to inquire |

|||||

| 2 | Phase |

Ph |

3 | |||||

| 3 | Rated voltage (Ur) |

kV |

3.3/7.2/12/24 |

|||||

| 4 | Specified electric current (Ir) |

A |

630/ 1250/ 1600/ 2000/ 2500~4000

|

|||||

| 5 | Fixed Frequency (fr) |

Hz |

50/60 |

|||||

| 6 | Rated short-time withstand current (main circuit and grounding circuit))(Ik) |

kA |

16/25/31.5 |

|||||

| 7 | Rated peak withstand current (main circuit and grounding circuit) (Ip) |

kA |

42/65/82 |

|||||

| 8 | Specified Short Circuit Duration (Main Circuit and Ground Circuit) (tk) |

s |

3 | |||||

| 9 | Specified short duration commercial frequency withstand voltage (Ud) |

kV |

28/50 |

|||||

| 10 | Specified Lightning Surge Withstand Voltage (Up) |

|

75/125 |

|||||

| 11 | Partial discharge capacity |

pC |

≥100 |

|||||

| 12 | Closing and opening device and auxiliary and control circuit's fixed power supply voltage (Ua) |

V |

110~220 AC/DC |

|||||

| 13 | Salt spray corrosion test for the casing |

Hr |

≥1000(RN10) |

|||||

| 14 | Seismic Resistance Level |

g |

X-axis ≥0.6 Y-axis ≥0.5 Z-axis ≥0.4 (Highest Level) |

|||||

| 15 | Internal Fault Electric Arc Test | Electric Arc Test Current | kA | 16/25/31.5 | ||||

| Electric Arc Test Current Duration | s | 0.5/1 | ||||||

| Internal Electric Spring Grade | - | IAC | ||||||

| Proximity type | - | Type A (F, L, R) | ||||||

| 16 | Ground switch characteristics level | kA | 25 | |||||

| s | 3 | |||||||

| - | E1/E2 | |||||||

| - | M1/M2 | |||||||

| 17 | Protection Level of Enclosure (IP) When box door is closed/when box door is opened |

- | IP4X/IP2X IP45 (weatherproof type) |

|||||

| 18 | Accessible Isolation Chamber | Circuit Breaker Compartment | Interlock Control Type | |||||

| Copper busbar compartment | Interlock Control Type | |||||||

| Electrical isolation chamber | Interlock Control Type | |||||||

| 19 | Operational continuity loss characteristics | LSC2B | ||||||

| 20 | Partition Type | PM | ||||||

| 21 | Electromagnetic Compatibility Level (EMC) | - | 3 | |||||

| 22 | Outer shell grounding continuity performance (DC30A) | V | 3 | |||||

| 23 | Cabinet material | - | Galvanized steel plate (not painted) | |||||

| 24 | Cabinet door (front and back), base, side panel material/paint color | - | SPHC/RAL7035 (standard), 5Y7/1 | |||||

Cabinet structure

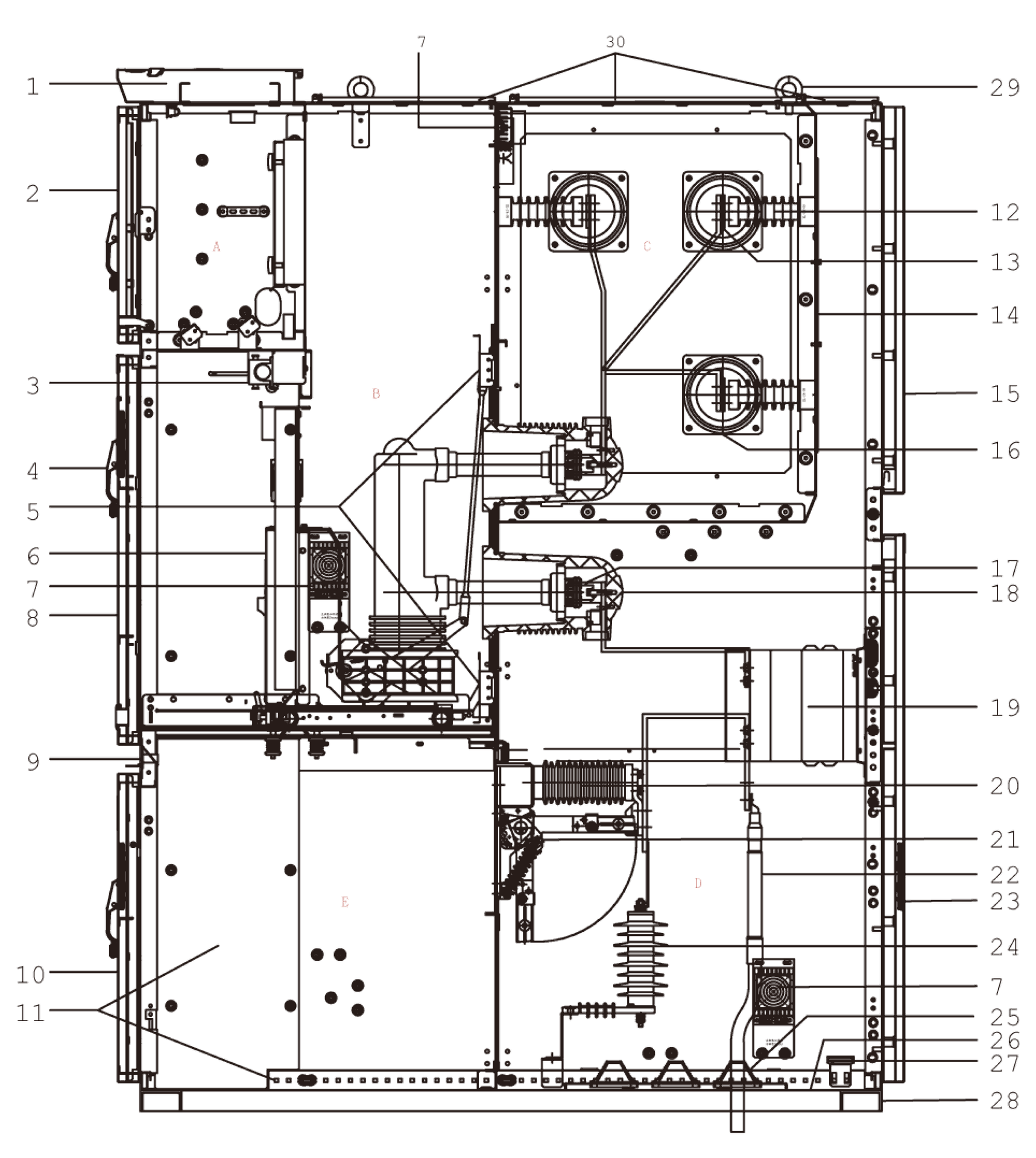

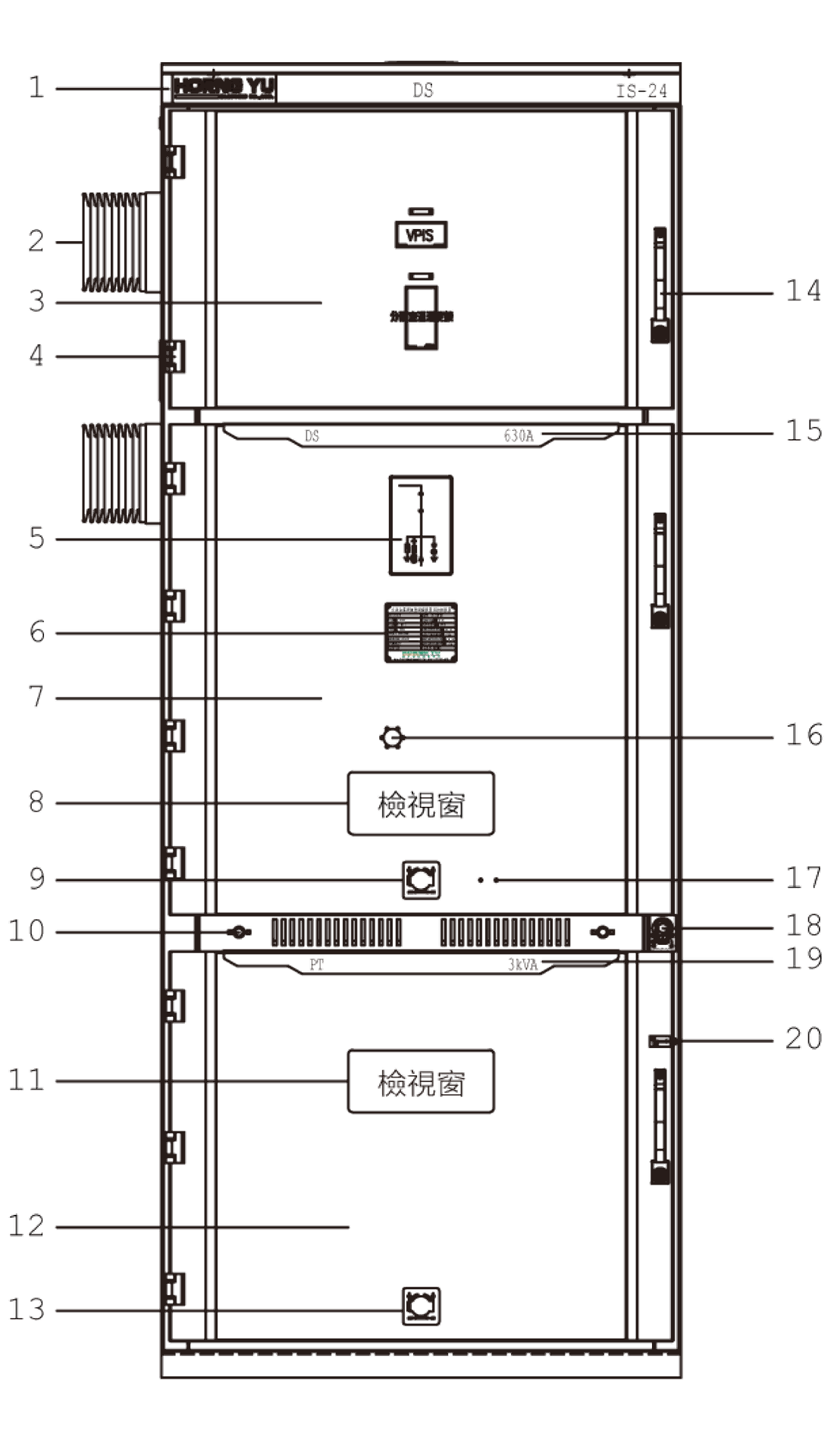

CB(DS)+ES

- A. Low voltage control room

- B. Breaker room (can install CB or DS)

- C. Convergent Discharge Room

- D. Electrical room

- E. Spare chamber

- 1. Nameplate Header with Control Cable Routing Slot

- 2. Low Voltage Control Room Door (SPHC Painting)

- 3. Circuit breaker control line plug socket (position interlock)

- 4. Door handle (lockable and sealable)

- 5. Upper and Lower Safety Shield (Metal)

- 6. Breaker Cart Type

- 7. Dehumidifiers for each partition (can be equipped with disturbance fans)

- 8. Breaker Room Door (SPHC Painted)

- 9. Panel (galvanized steel sheet)

- 10. Spare Room Door (SPHC Painted)

- 11. Control Line Metal Routing Slot

- 12. Isolation barrier

- 13. Horizontal Motherboard

- 14. Flow Distribution Chamber Partition (includes maintenance hole)

- 15. Rear door

- 16. Wall-penetrating Terminal Box

- 17. Circuit breaker static contact (silver plated)

- 18. Circuit breaker trip terminal box

- 19. Comparator

- 20. Surge Arrester

- 21. Ground switch

- 22. High-voltage cable

- 23. Lower back door

- 24. Lightning Arrester (Silicone Composite Type)

- 25. Electrical tower-type guard

- 26. Base plate

- 27. Horizontal Grounding Copper Bar

- 28. Install Base

- 29. Hanging Ring

- 30. Pressure release device

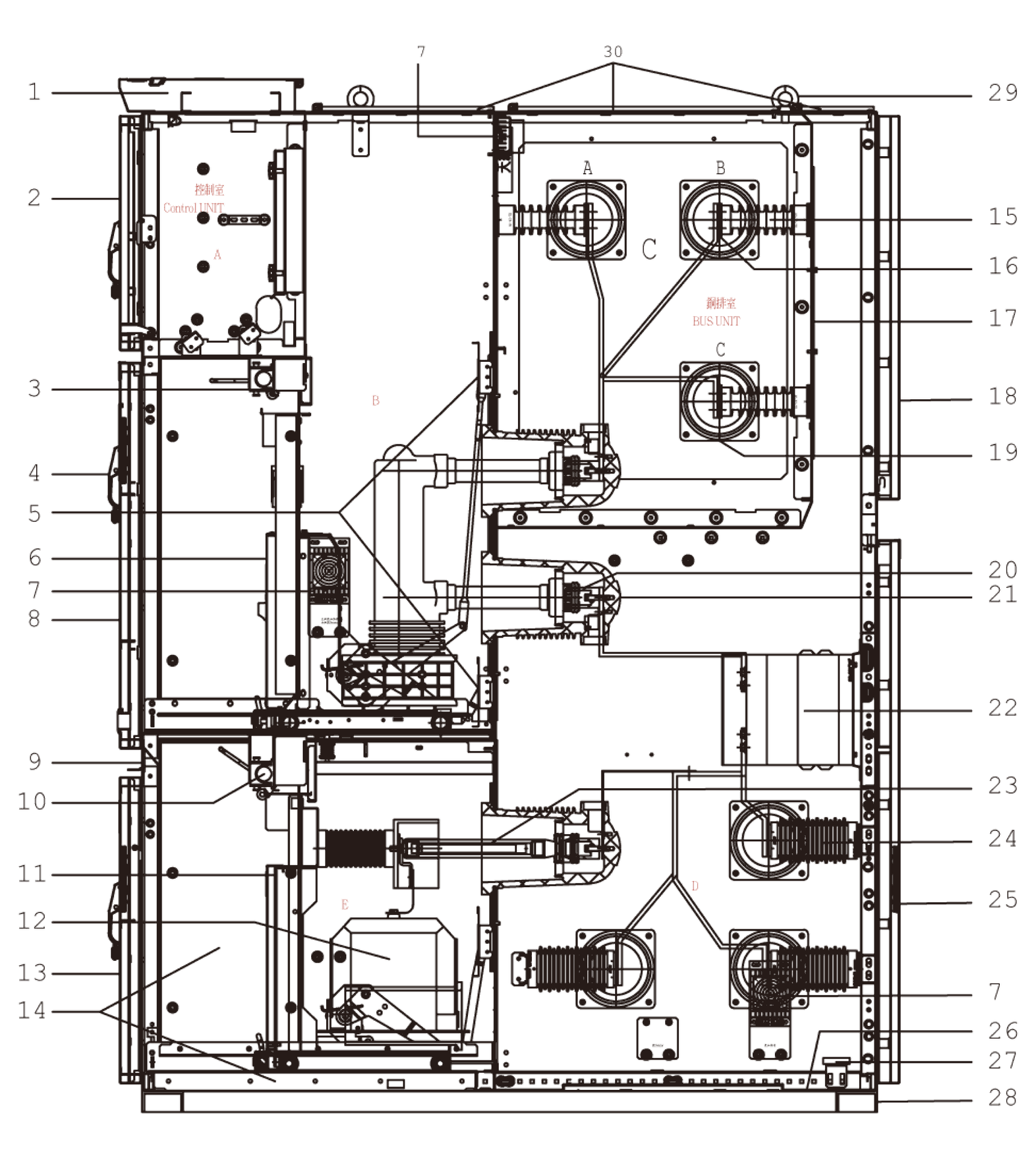

CB(DS)+PT

- A. Low voltage control room

- B. Breaker room (can install CB or DS)

- C. Convergent Discharge Room

- D. Electrical room

- E. Pressurizer chamber

- 1. Nameplate Header with Control Cable Routing Slot

- 2. Low Voltage Control Room Door (SPHC Painting)

- 3. Circuit breaker control line plug socket (position interlock)

- 4. Door handle (lockable and sealable)

- 5. Upper and Lower Safety Shield (Metal)

- 6. Breaker Cart Type

- 7. Dehumidifiers for each partition (can be equipped with disturbance fans)

- 8. Breaker Room Door (SPHC Painted)

- 9. Panel (galvanized steel sheet)

- 10. Pressurizer control line plug socket

- 11. Compressor trolley

- 12. Pressurizer

- 13. Spare Room Door (SPHC Painting)

- 14. Control line metal conduit

- 15. Terminal block

- 16. Horizontal Female Connector

- 17. Flow Distribution Chamber Partition (includes maintenance hole)

- 18. Rear upper door

- 19. Wall penetration termination kit

- 20. Circuit breaker static contact (silver plated)

- 21. Circuit breaker contact terminal box

- 22. Current Limiter

- 23. Press dedicated melting wire

- 24. Test electricity disturbance son

- 25. Lower back door

- 26. Base plate

- 27. Horizontal Grounding Copper Bar

- 28. Install Base

- 29. Hanging Ring

- 30. Pressure release device

Front View

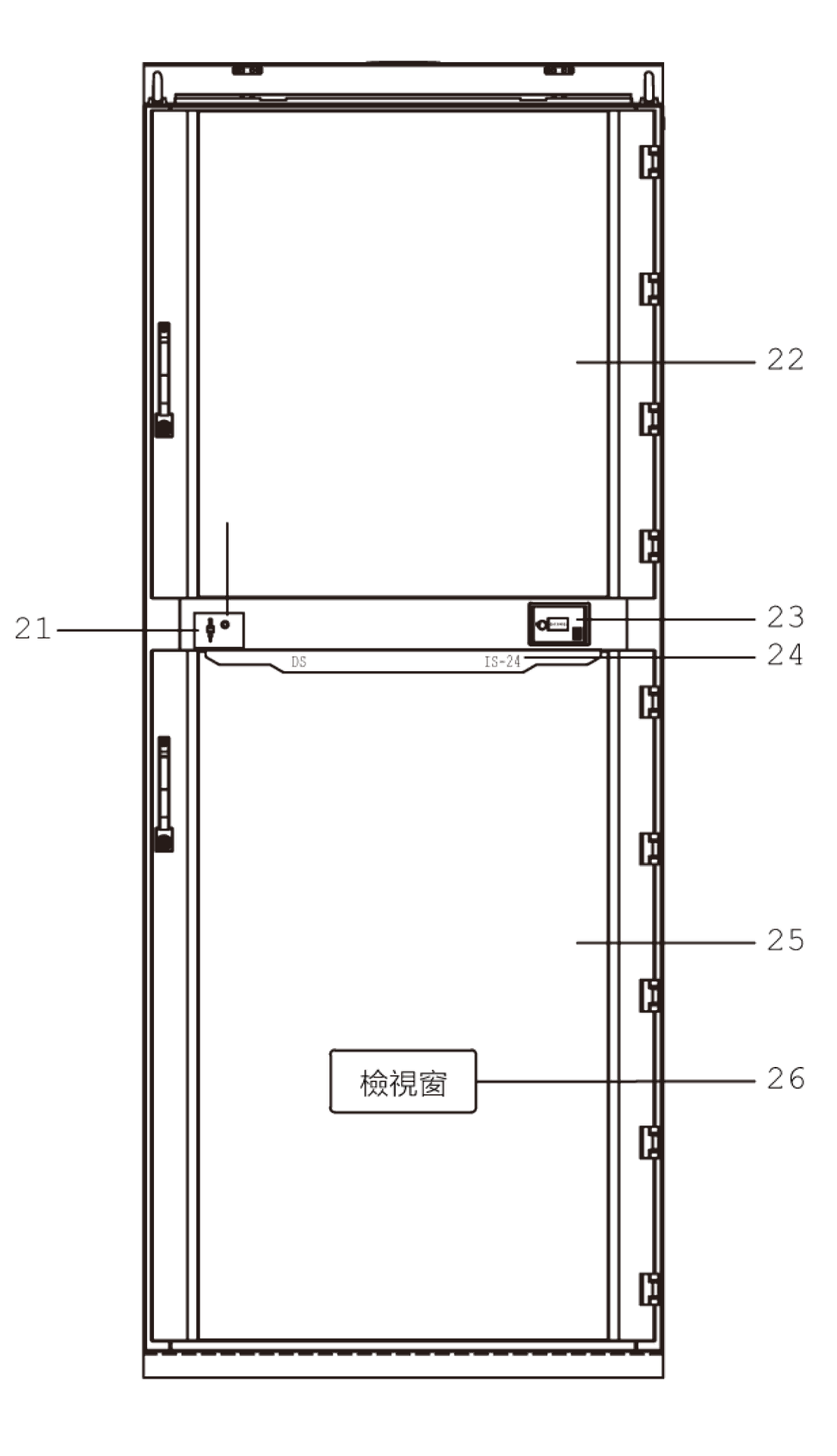

Rear View

- 1. Control wire routing slot under nameplate

- 2. Low Voltage Control Room Door (SPHC Painted)

- 3. Circuit breaker control line plug socket (position interlocking)

- 4. Door hinge (depressed door explosion-proof)

- 5. Simulated busbar (optional)

- 6. Type Specification Nameplate

- 7. Breaker room explosion-proof vent door

- 8. Circuit breaker chamber inspection window

- 9. Breaker Operation Hole (Lockable)

- 10. Circuit breaker transport vehicle positioning hole

- 11. Spare room inspection window

- 12. Spare Room Door (SPHC Painting)

- 13. Switchgear Trolley Operation Hole (Lockable)

- 14. Door handle (lockable and sealable)

- 15. Circuit Breaker Rated Current Nameplate

- 16. Circuit breaker emergency trip device (optional)

- 17. Door interlock emergency unlocking screw

- 18. Grounding switch operation hole (lockable)

- 19. Compressor Capacity Nameplate

- 20. Emergency Unlock Screw for Spare Room Door

- 21. Door Electromagnetic Lock (Optional)

- 22. Rear door

- 23. Wiring Room Lighting (Optional)

- 24. Nameplate and Model

- 25. Lower back door

- 26. Electrical Inspection Window

Common Questions

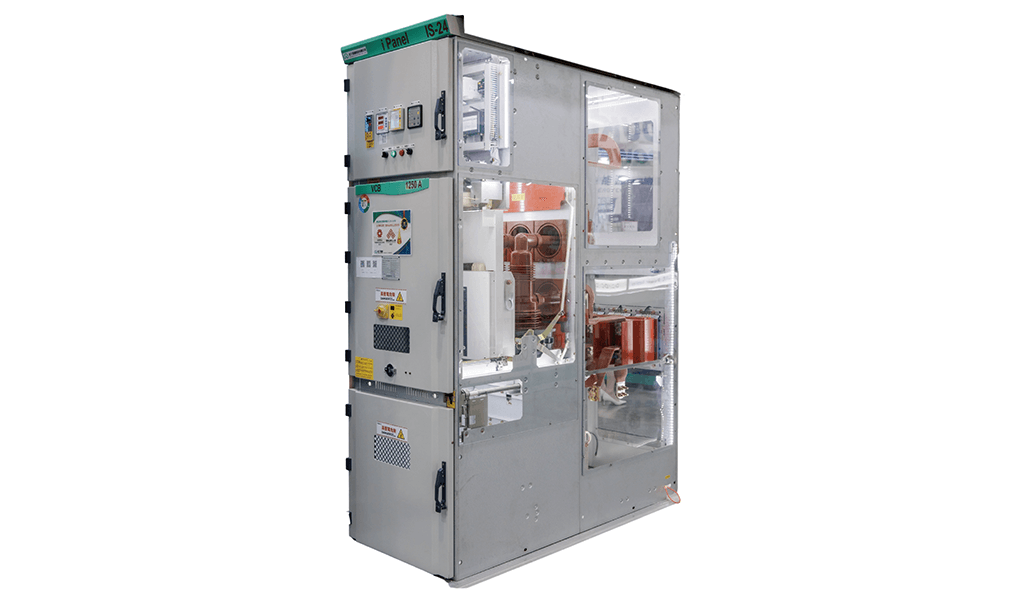

Q1a0What are the products IS-24 and IS-06?

A1

IS-24 is an intelligent high-voltage distribution panel (high-voltage switchgear and control equipment), suitable for high-voltage distribution systems.

IS-06 is an intelligent low-voltage withdrawable distribution panel designed for low-voltage distribution needs.

These two products belong to the series of intelligent distribution panels of the Electric Machinery, equipped with the electric cloud (iPanel) management system, combined with the AIoT concept, featuring self-diagnosis, automatic adjustment control, pre-warning, and load optimization and other intelligent functions; and can be integrated with cloud management platform for remote monitoring and IoT energy consumption analysis, thereby improving system safety and efficiency. Modularization and iPanelCad automatic drawing tools can also reduce design and production costs.

Q2 Which international standards do IS-24 and IS-06 comply with?

A2

IS-24 complies with IEC 62271-200/CNS 15156, and has passed type tests in international ILAC laboratories and Taiwan Power Research Testing Center.a

IS-06 complies with IEC 61439-2/CNS 61439-2, and has likewise passed tests in ILAC and Taiwan Power Research Testing Center.

Also collaborates with international brands like Siemens, Mitsubishi, and Schneider, integrating internationally certified components, equipped with export and cross-national project competitiveness.

Q30What are the technical specifications of IS-24?

A3

IS-24 type test certified specifications are: three-phase, 24 kV, 1250 A, short-time withstand current 25 kA × 3 s, 60 Hz, adopting LSC2B-PM interlock control design, with the German HVX24 circuit breaker and Nemie grounding switch.

Q4What are the capacity and applicable scope of IS-06?

A4

IS-06 is applicable for rated voltage up to 690 V, rated current up to 6300 A, and a maximum short-time withstand current of 100 kA, providing a reliable solution for low-voltage power distribution systems.

Q50Does Hung Yu invest in renewable energy applications?

A5

Yes, Hung Yu Electric Co. Ltd. leverages the intelligent energy cloud management system iPanel Electric Cloud to remotely monitor electricity quality online. It also integrates with solar power distribution panels and green energy solutions, supporting photovoltaic power plants and smart grids, aligning with ESG and net-zero carbon emission trends.

Q6Under increasingly stringent ESG and carbon emission requirements, how do these products comply with regulations?

A6

Hongyu Electric launched the ECO low-carbon distribution panel, which reduces carbon emissions through material and design, and provides carbon footprint tracking through cloud data, assisting enterprises in achieving ESG and net-zero emission goals.

The ECO low-carbon distribution panel adopts integrated molding processing technology, reducing material usage and carbon emissions while enhancing structural strength and durability, representing a product in line with international low-carbon trends.

Q7 What are the advantages of Hongyu in designing and manufacturing copper conductors?

A7

Hongyu Electric innovates with flat torsion technology, effectively reducing material connections, thereby lowering manufacturing time and material costs, improving operational efficiency, and achieving low-carbon environmental protection in response to carbon reduction policies.

Additionally, conductive components like woven soft copper belts and soft copper sheets can be customized, featuring excellent conductivity and rapid heat dissipation, widely applicable to high and low voltage panels and electrical engineering.

Q8 The factory already has power distribution equipment, why is there still a need to upgrade to IS-24 or IS-06?

A8

Due to the traditional distribution board only being able to 'passively supply power', the IS series distribution board combines intelligent monitoring, early warning, and remote management, allowing for early detection of anomalies, reducing the risk of power outages and equipment damage, preventing production loss. It is particularly suitable for high-demand applications such as semiconductors, healthcare, green energy, and industrial fields.

Q9 How does the IS series help me reduce electricity costs in terms of energy efficiency?

A5

IS-24 and IS-06 are equipped with the intelligent energy cloud management system iPanel Power Cloud, which allows real-time monitoring of electricity usage, analyzing peak loads, and providing optimization recommendations to help users adjust electricity consumption behavior and save electricity costs.

Q10 How to avoid situations where technical personnel are unfamiliar with intelligent distribution panels?

A5

The IS series is user-friendly, equipped with a touch screen and cloud-based APP, providing an intuitive experience similar to using smart home appliances; at the same time, Hongyu Electric offers comprehensive educational training and maintenance support, reducing learning costs.

Download File

Need assistance