Product Features

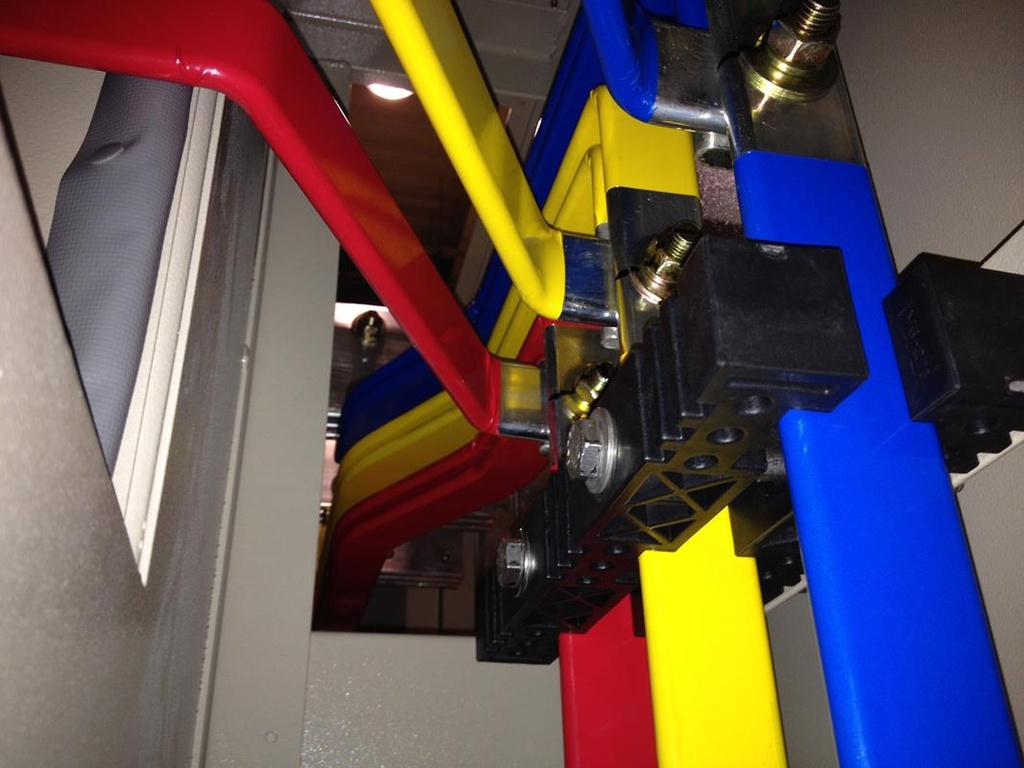

Innovative Technology

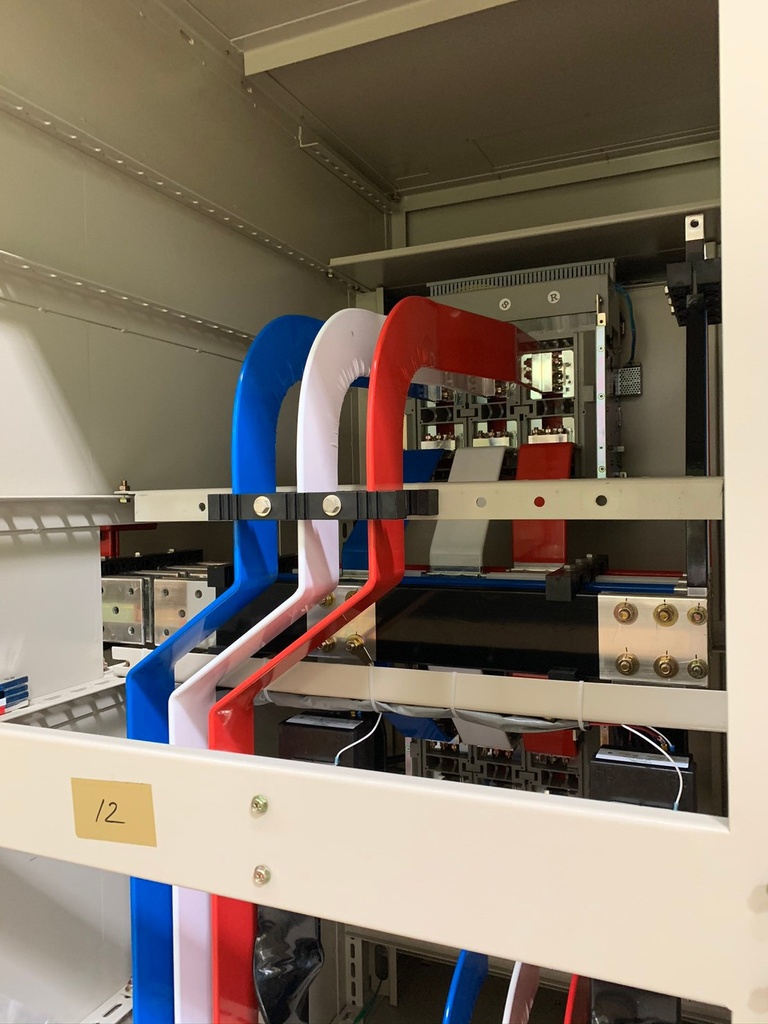

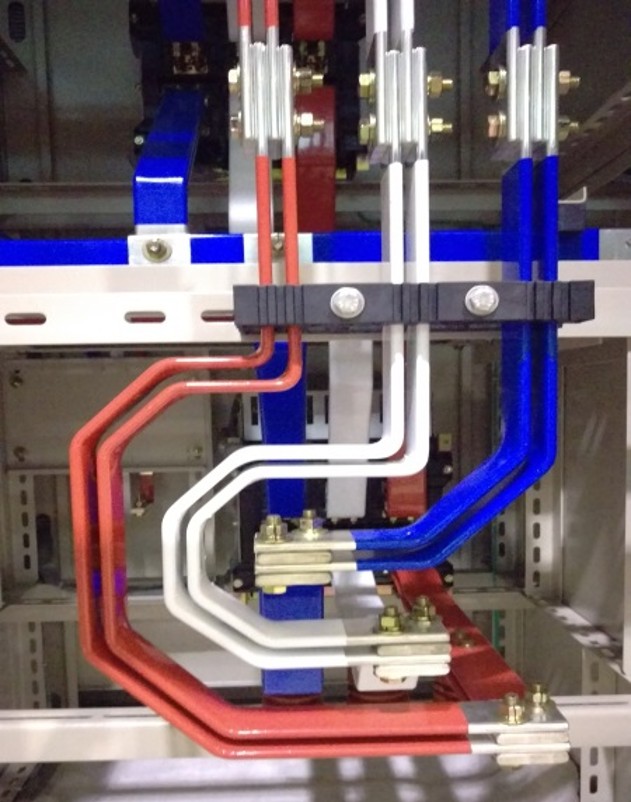

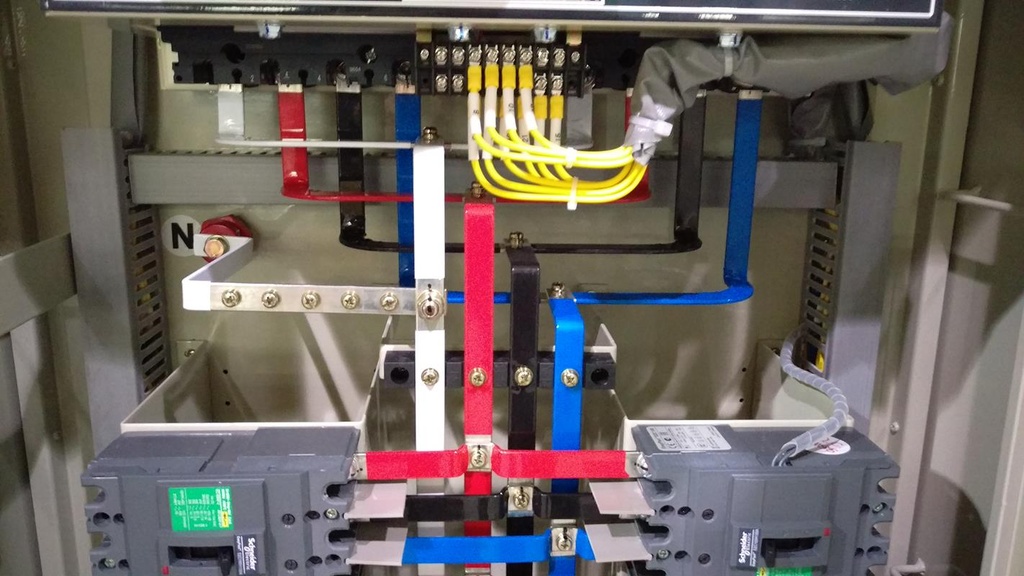

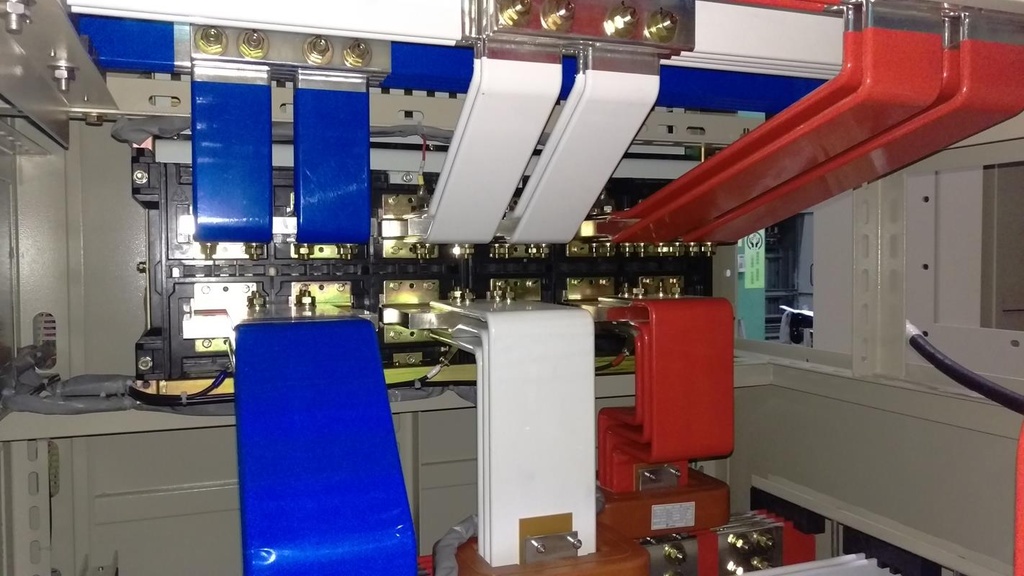

Reduce material connections for flat, twisted, and bent structures to implement low-carbon green manufacturing.

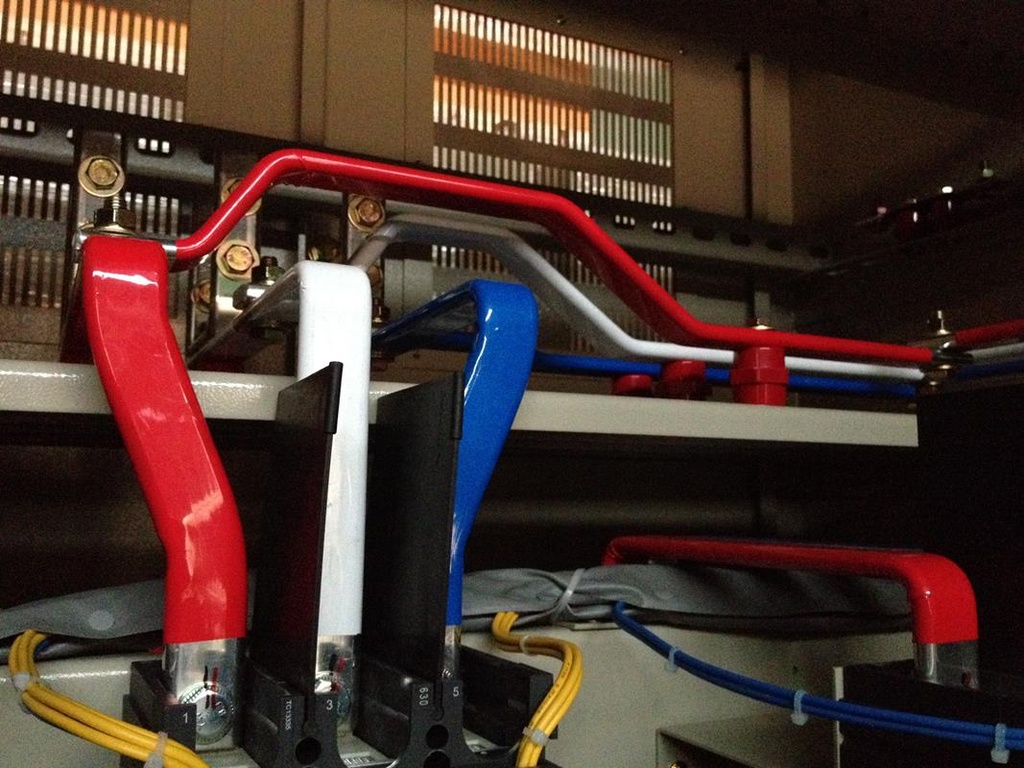

Superior Quality

German automation machines ensure product quality, precision feeding, and exquisite craftsmanship.

Innovative Technology Professional Services

From raw material import to multi-processing, all are handled by responsible units.

Frequently Asked Questions

Q1a0How to inquire about prices?

A1

E-mail 2D drawings (all dimensions marked in mm).

Q2 Can the copper busbar be modified?

A2

Bronze plates sold by our company can be provided with modification services (but drawings must be provided for feasibility evaluation)

Q3 How to deal with copper busbar oxidation?

A3

Can be re-polished and treated with anti-oxidation.

Q4a0Quotation types?

A4

All quotations include materials and processing (no customer-supplied materials, only processing services).

Q5 Lead time?

A5

Small quantity 7 days, larger quantities negotiable.

File Download

Need assistance